- Trutops Nesting Software

- Trutops Nesting Software App

- Trutops Nesting Software Free

- Trutops Nesting Software Download

- Trutops Nesting Software For Beginners

- Agam’s Design + Engineering team provides fully engineered solutions to customers and support for the fabrication specialists in the plant.

Trutops Nesting Software

Trumph TruTops Suite Laser. Efficient and process reliable NC programs. TruTops Laser enables you to program your TruLaser machines easily and reliably. Even at a high level of productivity your machine will run at its best. An efficient nesting module and various setting options will ideally arrange and place different parts on the sheet.

A Diverse Team of Designers Working Together.

Agam has six designers on staff, each of them with a strong background in various fields of design. They support the project management teams, providing fully engineered solutions to customers and detailed fabrication drawings to production specialists in the plant.

AGAM designers have a large variety of design, engineering, and modeling software available to achieve their tasks. Each designer attends industry education conference classes and keeps their skills to the highest level in this fast-evolving field of expertise.

- SOLIDWORKS is a high performance design and engineering software, and has become a standard platform for product development and manufacturing throughout the world.

- Agam uses SolidWorks to engineer solutions for customers, delivering an engineered solution at the time of estimating.

- Customers can then review such quotes to fully understand the solution offered, and eventually discuss design options and cost alternates.

- Agam also uses SolidWorks to engineer its own parts, such as the design of a plastic end cap and its pertaining mold. Such designs are then sent to the mold maker and the injection mold company, which can make suggestions through the SOLIDWORKS model on items such as material flow, tool wear, product aspect, manufacturability, and costs.

Trutops Nesting Software App

- Agam uses AutoCAD as a basis for 2D and 3D drawings, whether for in-house work such as curves or for engineering and design support for customers.

- Agam can provide efficient drawings in half a day or less for projects, depending on their level of complexity, along with engineering details when fabrication teams need supporting data.

- Agam also designs tools and jigs on AutoCAD. A perfect example is a drilling jig for the VS76 Extrusion as shown above.

- With CAMWorks, we use each machine to the best feed rate, with safe processes and cost-effective programming alternatives.

CAMWorks allows our designers, production specialists, and machinery workers to all work together. Before a single machine operation is started, the software can calculate the maximum production speed, and feed and path, optimum bit size, and depths of each operation.

TruTops Overview

Agam programming systems optimize machine utilization, material yield, and reliability. Software delivers data instantly, providing information on what material to use and how long it will take. It allows Agam to share data with customers, such as turnaround time and costs, with the highest reliability factor.

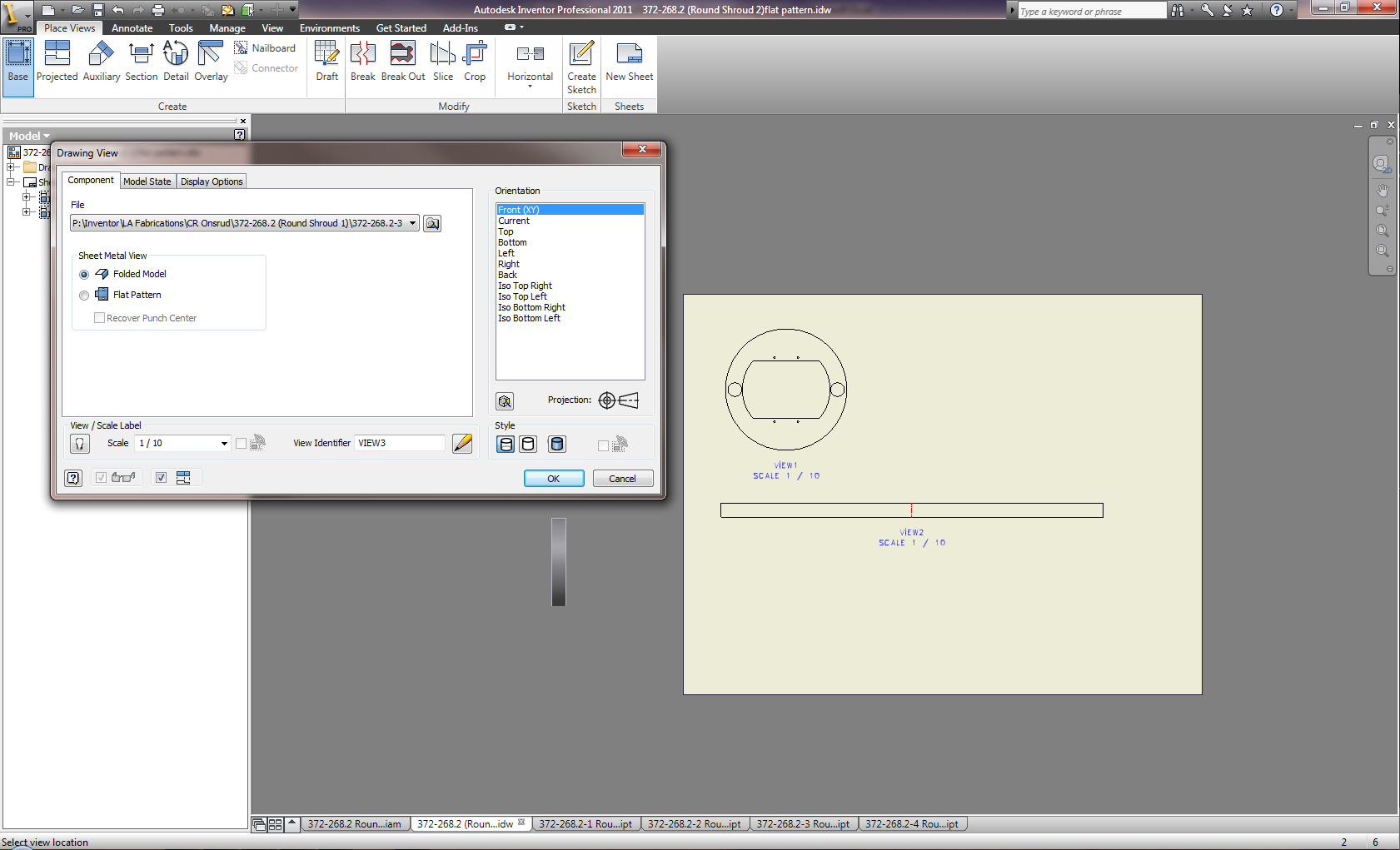

TruTops: Nest

TruTops: Laser – Production Ready 3D Sheet Metal Designs

Three-dimensional design ideas can be quickly translated into reality. Agam’s designers are able to create realistic and practical designs minimizing rework, and they can offer alternate design solutions with minimal rework and delays.

TruTops Unfold: Data for Production

After a design is approved, the TruTops unfold software allows Agam to produce 2D blanks from 3D designs. The software reverse-engineers the factors such as metal thickness, radiuses, and automatically selects the tools and the process sequence.

TruTop Bend

This software optimizes tool selection and bending sequences. A detailed setup plan is automatically generated by the software, so the designer can run a simulator to validate the intended process. This prevents collisions and details the work for the machine operator. For more information, see CNC Bender.

Trutops Nesting Software Free

With the Multilight feature – developed by Maxwell – the light intensity and color variations can be adjusted in real time without the need to re-render. Agam’s designers use Maxwell Render through the plug-ins for SolidWorks and Autocad. This means that the rendering is directly integrated with a vector file, and the design that’s been engineering is the design that’s rendered.

When time is of the essence, and the render is approved, then the engineering background is there, ready to use. Manufacturing can start immediately without going back to the drawing board.

Trutops Nesting Software Download

- Office Environment

- Extrusion Arrangement

- Office Cubicle Environment

- Customer Experience Concept

Trutops Nesting Software For Beginners

We specifically use 3D Studio Max in the fields of shading and material design, texture assignment and editing, and 3D modeling/texturing. Because 3D Studio Max is fully integrated with our technical drawings in formats such as AutoCad and SolidWorks, Agam industrial designers can move back and forth from engineering specifications, design objectives and renderings – high resolution assets and complex, detailed files. Communication with clients’ project teams is optimized and workflows are streamlined.

- VS76 5-Way Catalog Render

- Miter Connector Catalog Render

- iPad Case and Swivel Mount Catalog Render

- Stainless Steel End Cap Catalog Render